Standard FKM Shaft Seals

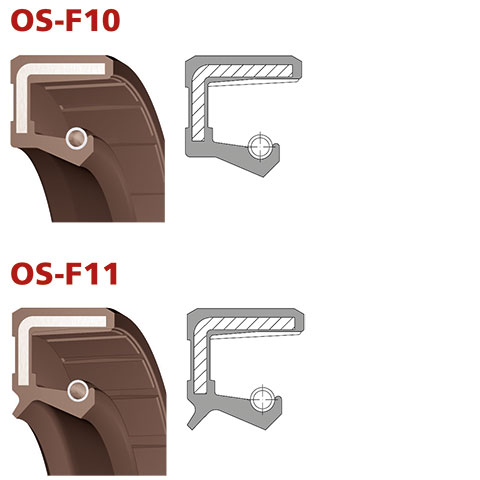

Typ OS-F10 and OS-F11 with metal case fully covered

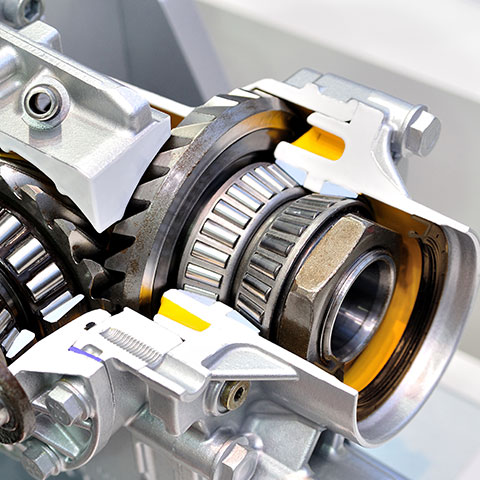

Shaft seals are rotary seals. They are used to seal rotating or swivelling machine elements (mainly shafts). The areas of application are diverse and can be found in all areas of mechanical and apparatus engineering.

For the types OS-F10 and OS-F11 the standard material is FKM 80 brown, the spring made of stainless steel 1.4301 and the metal case out of carbon steel according to DIN EN 10139.

As further elastomer material NBR, VMQ, ACM, HNBR, CR and EPDM can be used.

The anyseals standard Rotary Seals in FKM are the types OS-F10 and OS-F11.

The latter has an additional protective lip against intrusion of external contaminations. There are good reasons to use exactly this design, because it allows a universal use! The metal case is fully covered with elastomer and the sealing lip is supported by a stainless steel spring. The question of the exact purpose, which often can not be answered anyway, may be omitted. However, if it is known that the FKM elastomer is only provided for thermal reasons, of course, the less expensive OS-A10 design can be used without risk!

anyseals has more than 1000 dimensions available from stock. All information you‘ll find 24/7 in our eShop shop.anyseals.eu.

shop.anyseals.eu

For the types OS-F10 and OS-F11 the standard material is FKM 80 brown, the spring made of stainless steel 1.4301 and the metal case out of carbon steel according to DIN EN 10139. As further elastomer material NBR, VMQ, ACM, HNBR, CR and EPDM can be used.

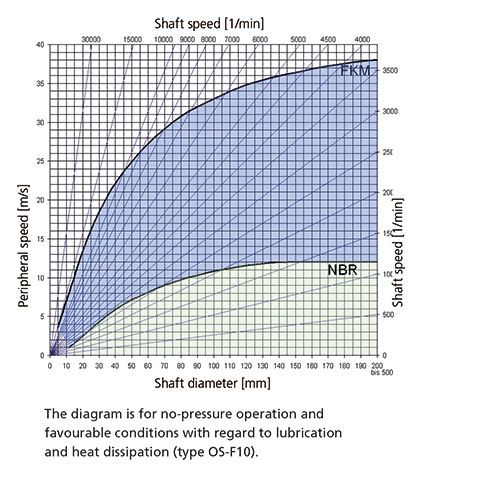

Application parameters for the standard materials combination:

Temperature: -25°C to +160°C

Pressure: depressurized, max. 0,05 MPa

Shaft speed: acc. to chart

Media: mineral oil based lubricants, synthetic lubricants, fuels, aromatic and chlorinated hydrocarbons, good resistance to many chemicals